- Problem Recognition

Knowing and understanding how learning curves impact durations is another “tool and technique” that planners / scheduler can utilize to produce more realistic and achievable schedules. It can be used for scheduling (durations) as well as for costs.

It is applicable whenever there is a single activity or series of activities (“fragnets”) which repeat on a project. Examples of this are repetitive floor layouts in a hotel or high rise office building, installing pipelines, hanging doors, installing electrical lighting or any other activity or series of activities which repeat.

In this blog simulation will be applied to specific fabrication activity called double joint of subsea linepipe which conducted in construction site. The works has started for several weeks and in this blog we’ll try to count completion duration based on productivity.

- Feasible Alternatives

Several variable that known:

- It is known that target productivity is 1unit/day

- The production would be 6 days a week, 2 shifts

- Target completion for 45days

- The work has been commenced and data has been collected for 9 unit out of 39

Learning curve is quite dependent into learning rate that we apply. Therefore in this blog we’ll try using 2 learning rate:

- 1st based on the expectation by 80%

- 2nd based on observation of actual values.

- Outcomes

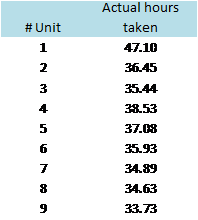

Actual Data:

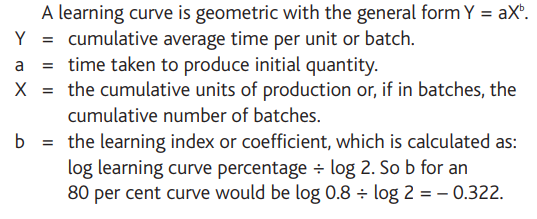

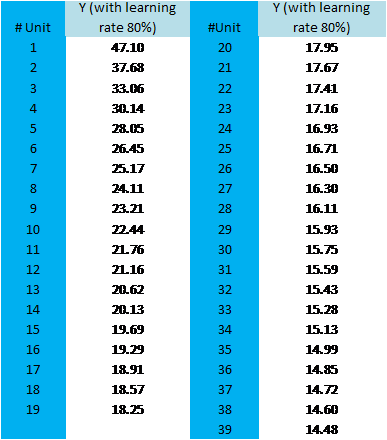

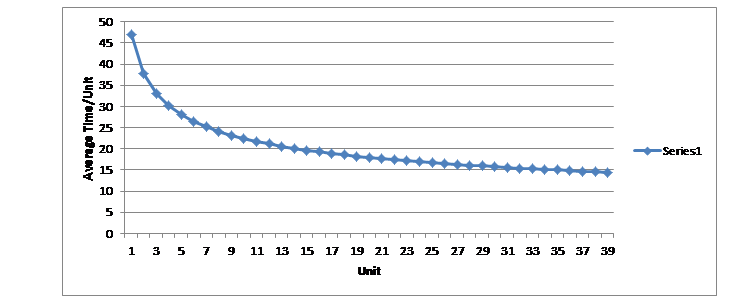

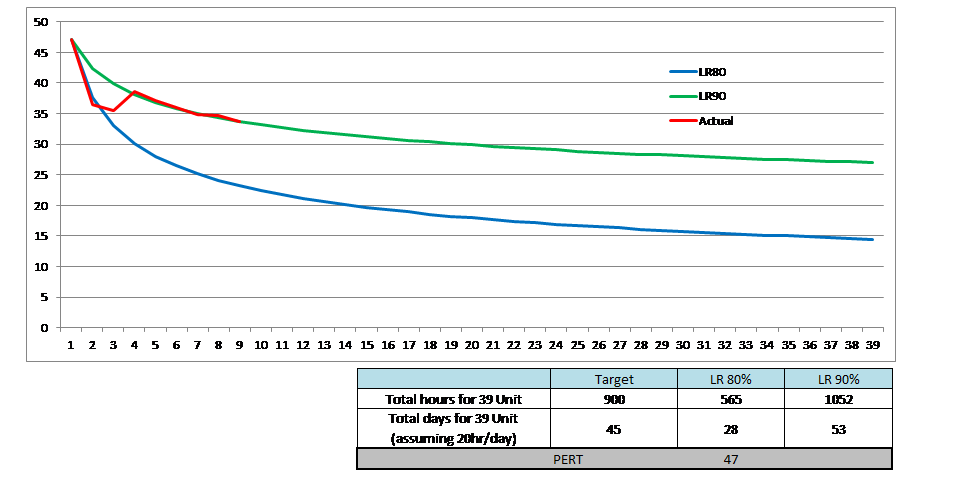

Option 1: Learning curve implementation using start point takes 47hours for 1 unit production. With learning rate 80% (standard) until 39 unit, using formula:

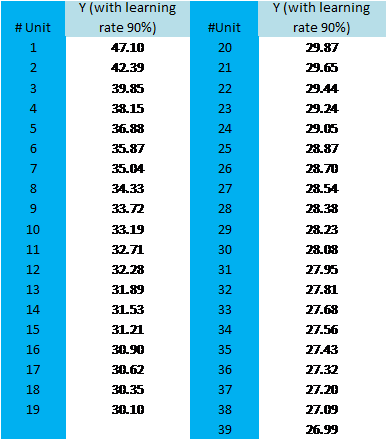

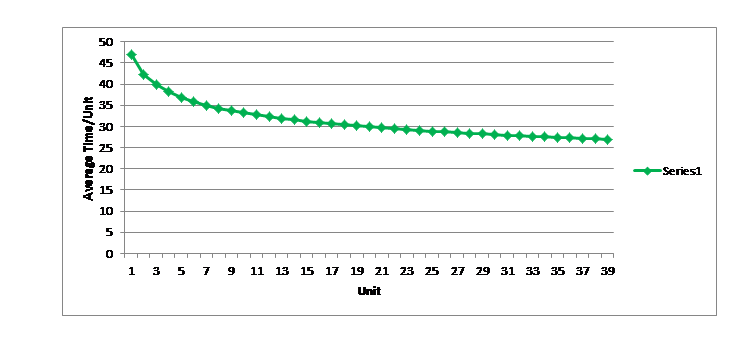

Option 2: Learning curve implementation using start point takes 47hours for 1 unit production. With learning rate as per observation seems takes lower learning rate, therefore we’ll use 90% learning rate until 39 unit

- Selection of criteria

- we’ll see which learning curve model provides closest result to actual productivity

- Check whether original target completion on 45 days still reasonable.

- Analysis & comparison

Based on learning curve simulation above, we could see at first the productivity is following 80%, but starting 3rd until 9th it follows 90% learning rate. And if we apply PERT with most likely 90% learning rate we get 47days to get completion, while 53days if only using learning curve 90%.

- Selection of preferred alternative

Back to selection criteria:

- we’ll see which learning curve model provides closest result to actual productivity: the answer is learning curve with rate 90%

- Check whether original target completion on 45 days still reasonable: if we apply PERT and considering all alternatives result 45 days still reasonable with note to slight delay. However, we need to be careful because original learning curve 90% is showing 53 which quite significant potential delay compare to target.

- Performance monitoring

Schedule analysis need to be conducted immediately to analysis 53days potential production and its impact. If it’s on critical then need to start consider fast track or crashing and other mitigation.

Reference

- Acquiring Manpower for the Project: http://www.planningplanet.com/guild/gpccar/acquiring-manpower-for-the-project

- BHATTI, AHMAD TARIQ (2012) HTTP://WWW.SLIDESHARE.NET/ATBHATTI/LEARNING-CURVE-15317153

- BROOKFIELD, BILL (2005) MANAGEMENT ACCOUNTING – DECISION MANAGEMENT HTTP://WWW.CIMAGLOBAL.COM/DOCUMENTS/IMPORTEDDOCUMENTS/FM_APRIL_05_P44-47…

- MIRSAU, ALLEN (2014) HTTPS://WWW.YOUTUBE.COM/WATCH?V=QALPY5INOWW

- Wibowo, G. (2014). W9_GW_Impacts of Overtime on Productivity. Retrieved from https://kristalaace2014.wordpress.com/2014/04/22/w9_gw_impacts-of-overtime-on-productivity/

Another very well done topic, Bu Innar!!! Just curious, do you know (or can you maybe GUESS) what happened between the 2nd and 5th Unit to cause the productivity to jump from the 80% Curve to the 90% learning curve?

That is a very interesting set of data and if you do know (or want to guess?) that may be a topic for another blog posting.

Keep up the good work and really happy to see you catching up!!

BR

Dr. PDG, Jakarta

LikeLiked by 1 person

Thank you Pak Paul, yes for that specific case it is related to equipments issue which impacting several days of productivity – and after that, the improvement rate is not that significant either due to repair issues therefore the productivity remain following 90%. Not sure what method i can use to reflect the analysis in blog.. meanwhile i do have another topic for next blogs, but i’ll try to find way to put it in one of them.. Thank you for the suggestion Pak Paul

LikeLiked by 1 person